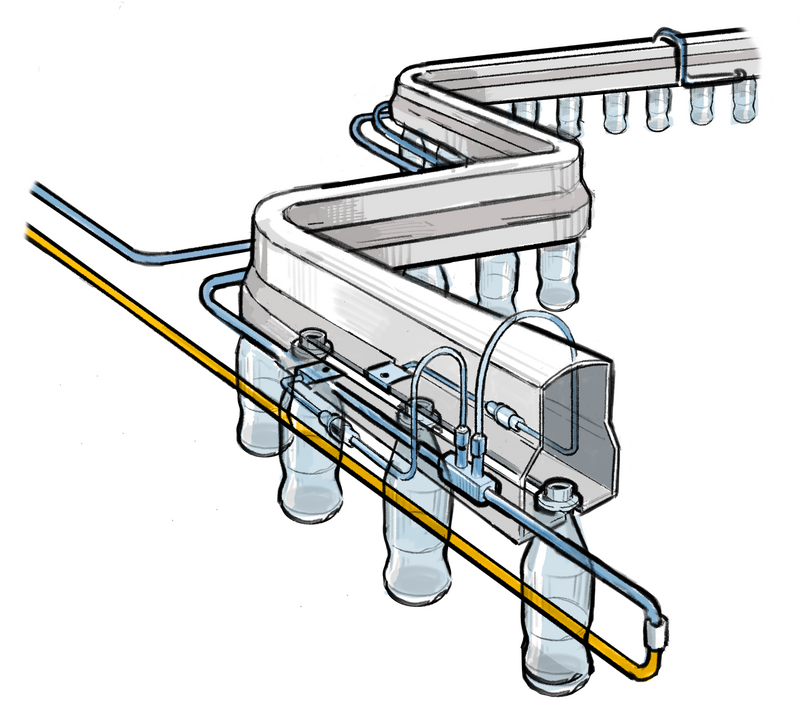

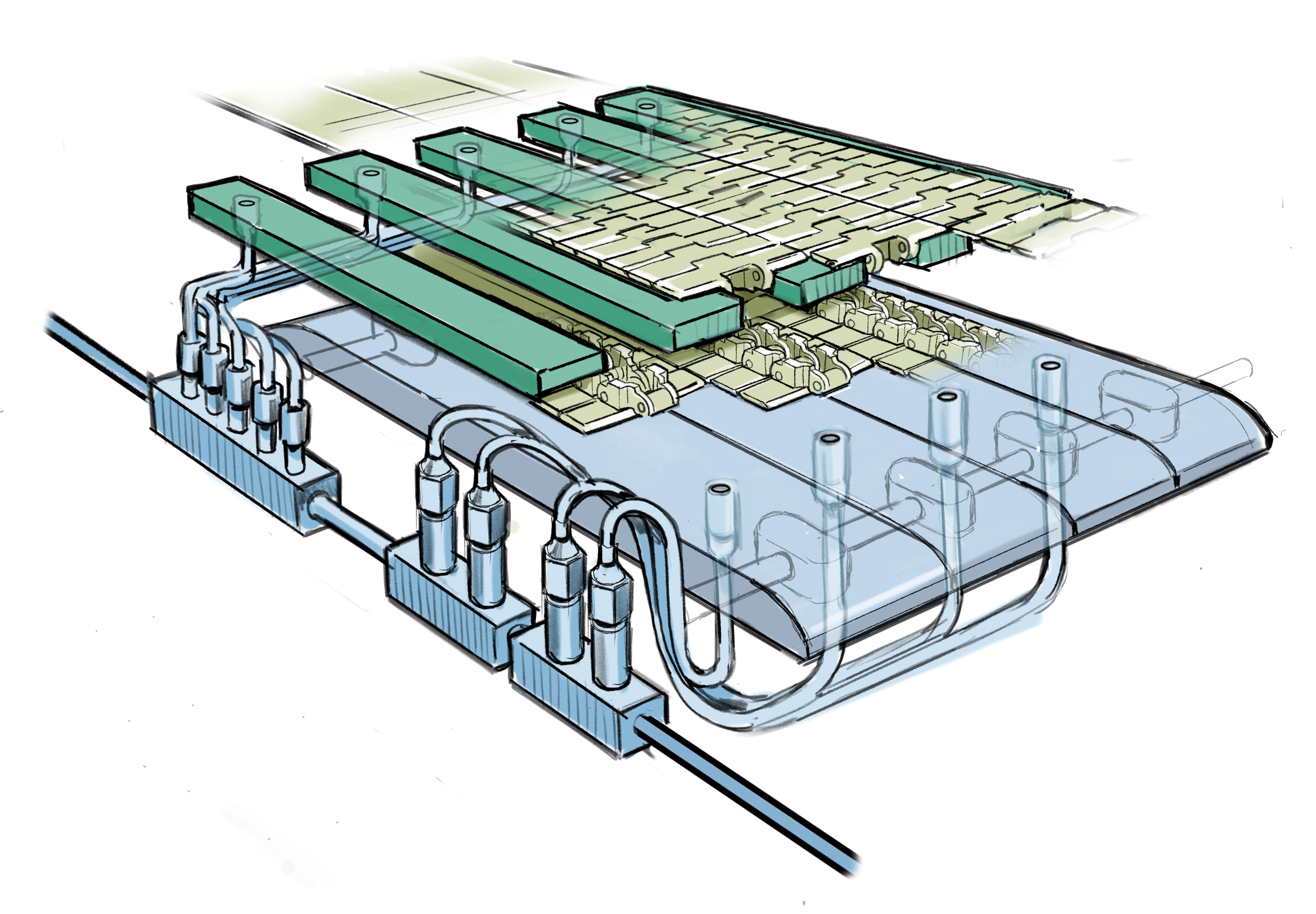

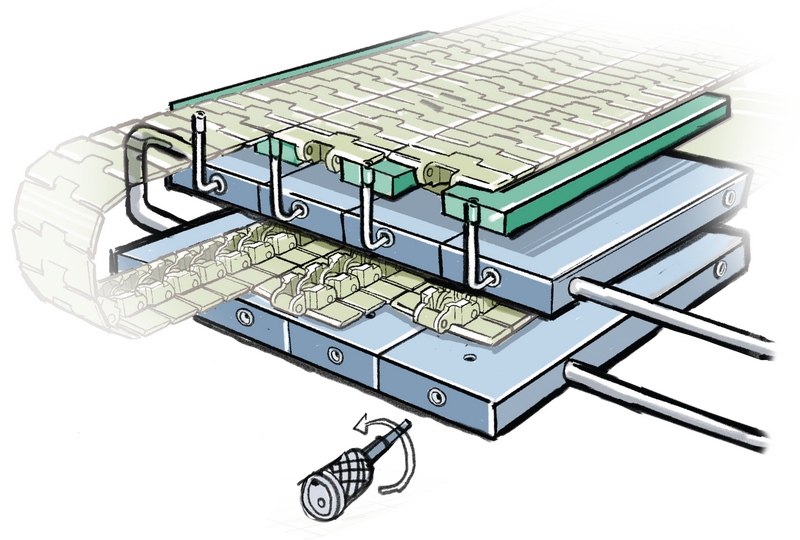

MicroDry® is a revolutionary, sustainable, advanced custom-fit dry conveyor lubrication technology, developed & patented by CHP.

As a leading engineering company designing, manufacturing, installing and servicing innovative state-of-the-art lubrication solutions, ranging from small-scaled installations up to large turnkey projects, successfully supplying to a wide range of international customers for the past 20 years.

MicroDry® conveyor lubrication and cleaning:

The revolutionary drop

DLT-333®, a unique coating

Our unique coating is biodegradable, 100% water- & silicone-free, and FDA approved. This high effective and stable microscopic film-layer assures no drip-off when used with MicroDry® Air. On PET air Conveyors it is considered as a safe coating because of the extreme low consumption and the specific method of application to eliminate bottle jams.

The revolutionary drop

DLT-333®

Our unique FDA approved lubricant is biodegradable and 100% water- & silicone-free. This high effective and stable microscopic film-layer assures no drip-off when used with our MicroDry® Slat technology for lubricating your conveyor belts.

The revolutionary drop

CLA-252, a high performing cleaning agent

CLA-252 is our degreasing foaming agent for conveyor cleaning, to remove spillages of food, beverages and oily substances. Our cleaning agent is biodegradable, and compatible with most commonly used materials used in the food & beverage industry.

Our way of working

-

1

Custom Design

We design and manufacture your custom MicroDry® conveyor lubrication, coating and cleaning technology.

-

2

On-site installation

We perform on-site installation by our in-house skilled technicians.

-

3

On-site installation

Our engineers provides a one-day in-house training about out conveyor lubrication or cleaning solution

-

4

Service team

Our servicing team is always ready to maintain your MicroDry® conveyor lubrication, coating or cleaning system.