KraussMaffei technologies are world leaders in the recycling field.

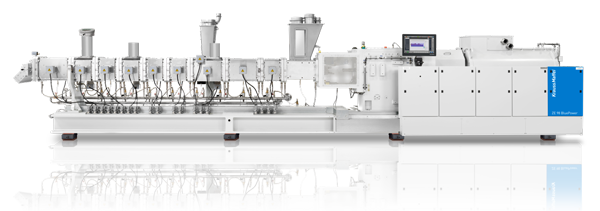

KRAUSSMAFFEI RECYCLING TECHNOLOGY: High-efficiency, high-performance solutions for both physical and chemical recycling—or a combination of both—to meet the most demanding applications. Leveraging KraussMaffei’s renowned co-rotating twin-screw technology, we deliver solutions that achieve a higher degree of material purity. The more ambitious the project, the more competitive our solutions become.

KraussMaffei also operates the largest recycling laboratory for tests and trials, helping you determine the most effective way to reuse your waste and achieve your desired results.

Applications:

Material: rLDPE

Technology: purity recyclingLine (mechanical) or purity solventLine (solvent-based).

Material: rPET

Technology: purity glycoLine (chemical) or purity recyclingLine (mechanical)

Material: rHDPE

Technology: purity recyclingLine (mechanical) or purity solventLine (solvent-based).

Material: rPS

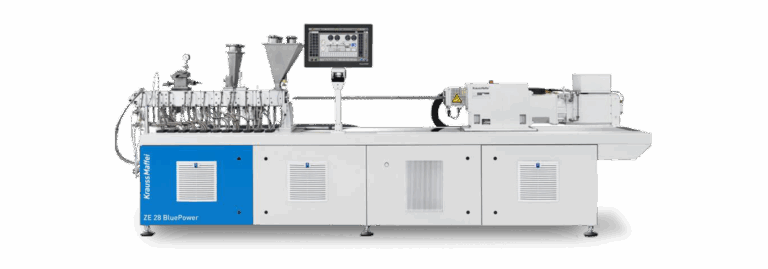

Technology: purity recyclingLine (mechanical) with ZE BluePower twin-screw extruder

The ZE BluePower twin-screw extruder series stands out for numerous innovative features in terms of energy efficiency and process engineering. This series is designed to meet the most demanding market challenges as to output rate, product quality, process reliability and flexibility. Benefit from the multitude of energy-saving innovations and the perfectly matched components of this trendsetting twin-screw extruder series.

Benefits:

Highlights

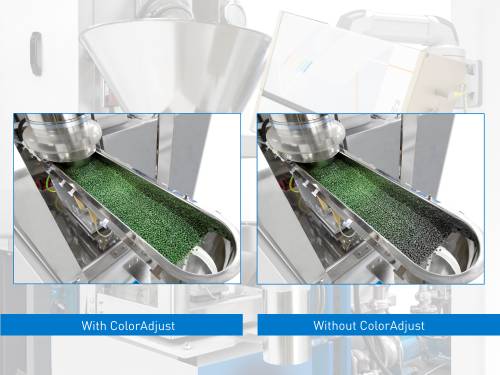

APC colorAdjust not only monitors color fluctuations without contact, but also directly adjusts them back to the color setpoint in the event of the smallest deviations. In this way, the processor achieves a high level of reproducibility even with input goods with a varying color spectrum. The color setpoint is quickly reached both when starting up the compounding or recycling process after a standstill and after a color change.

Benefits:

Highlights

Recycling and Compounding in one step

purity compoundingLines are rated for throughputs of up to 6 t/h. The main benefit of this extrusion solution is the direct conversion of reclaim material into high-quality compounds in a single heat.

Benefits:

Highlights

With the extensive modular range of barrel sections and screw components, the ZE 28 BluePower laboratory extruder is a future-oriented machine. It also provides a significantly larger processing window for small batch production with the screw diameter of 28 mm, its diameter ratio Da/Di of 1.65 and high performance of 42 kW with a screw speed of up to 1200 rpm.

Benefits:

Highlights

Individual extrusion solutions

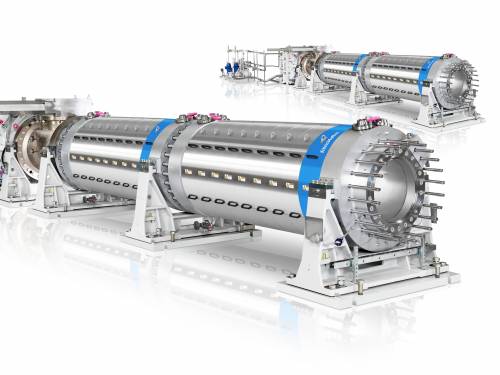

Single- and twin-screw extruders from KraussMaffei are valued as reliable and efficient technology in solvent-based recycling. Compared to other solutions, they are equipped with many process engineering innovations. They offer the plant operator great safety and efficiency. We develop sustainable and cost-efficient solutions with our customers.

Benefits:

Highlights