Looking to Improve friction reduction using PTFE, elimination of damage to packaging and labels, reduction of chain wear and removal of bacterial growth Specialized Dry Lubricant is the way to go.

Plastrading’s partnership with Specialized Dry Lubricant provides the right solution for your food production lines and beverage production lines.

Our scope of supply extends to:

RM2000T® is an oil based PTFE lubricant which is completely food grade. It is the result of a special process that ensures the Teflon remains in suspension in the oil for long periods. This capability means it can be dosed in small quantities onto the specific conveyer parts where it is needed knowing the Teflon will be where it is required.

Other “dry lubricants” are aqueous based emulsions of silicone and water, which promotes bacterial growth. RM2000T® has an oil base and is totally inert and will not promote bacterial growth.

Some lubricants are water miscible and will mix with juice and milk spilled on the line making the chain sticky and increasing friction on the package. RM2000T® cannot mix with spillage and, as it contains PTFE, expels spilled product from the chain.

Other lubricants are sold to the customer on “added value calculations”. In other words, the more you save, the more money you will pay for the lubricant and its “free” system. RM2000T® is sold by the litre and our system is guaranteed for 5 years and wholly owned by the customer. This means ALL of the savings and benefits remain with the customer and you only pay for what you use.

RM2000T Dry Lubricant is available in:

- 6L Boxes (6 x 1L bottles)

- 10L Boxes (2 x 5L bottles)

- 205L Drums

(MOSH & MOAH FREE) specialist Lubricant Ltd has created new RM2000MMF MOSH & MOAH lubricant presently on the market.

The solution to this problem

We at Plastrading in partnership with Specialist Lubricants Ltd take client and customer safety very seriously and to that end we have produced RM2000MMF (MOSH MOAH Free) and RM2000 CAN MMF to safeguard our clients and their customers from any concerns now or in the future.

Specialist Lubricant Ltd has created new RM2000MMF MOSH & MOAH free the only MOSH/MOAH free conveyor lubricant presently on the market.

RM2000MMF® is synthetic oil-based conveyor lubricant consisting of evenly distributed PTFE particles. It was designed for use in food & drink and packaging industries.

RM2000MMF® was developed to be used as a lubricant for chains and production lines, but it is also recommended as a lubricant for other gliding surfaces in food production environment, drink and packaging.

RM2000T Dry Lubricant is available in:

- 6L Boxes (6 x 1L bottles)

- 10L Boxes (2 x 5L bottles)

- 205L Drums

LINE LUBRICATION - PUMPS AND CONTROLLERS

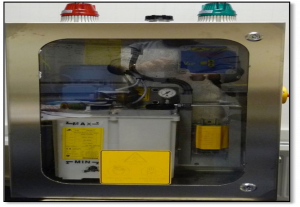

COMPLETE DRAGON LUBRICATION SYSTEM with 6L TANK

The Dragon System is a single line lubrication system. It has no need to circulate the lubricant as Specialist Lubricant’s RM2000T® is a stable solution and will not separate under pressure.

The Dragon System can be controlled via the LC30 control system when used on a single line. Where multiple lines are using a single system, the line controllers can operate solenoid valves to each line, opening or closing the feed of lubricant.

- A single Dragon Unit can be used to fulfil the lubrication needs of up to 10 lines

- A single Dragon Unit can lubricate up to 400 lubrication points

- Simple operation

- A timer controls the lubrication cycle

- Single Potential

- Free Input allows control from customer equipment

- Single stainless steel enclosure houses the pump unit and the control module (VIP5)

- Operating Pressure 40 Bar

- Tank Capacity of 6 Litre

- Floating Switch for Low Oil Level Monitoring

- 230V and 110V Supply Voltage available

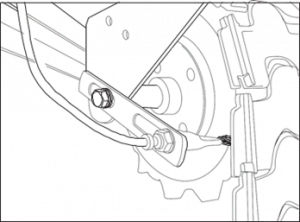

DRAGON PUMP

The Dragon Pumps is extremely compact and versatile and particularly suitable for lubricating presses, reducers, machine tools, guides and chains. The gear pump interlocks the lubrication circuit and is available in two versions: the first has a flow rate of 350 cm³/min (21.3 cu.in/min), the second has a flow rate of 500 cm³/min (30.5 cu.in/min), both operating at 1500 rpm. The Dragon pump can be customized according to the different needs of the user thanks to a wide range of electric motors and tanks available. It is also possible to equip the Dragon pump with an Integrated Control Panel (entitled VIP Controller, which allows the transmission of programs using infra-red rays) or with a Manual Control device which has to be connected to a separate electronic equipment.

Key Features:

- At intermittent running is 70 bar (1029 psi) with a three

- Phase motor and 40 bar (588 psi) with a single

- Phase motor under operating temperature between +5 ÷ +40 °C (41 ÷ 104 °F)

- working time of 5 minutes with 1:1 pause ratio

- At continuous running is 30 bar for both single

- Phase and three

- Phase motor under operating temperature between +5°÷ +40°

VIP5 Controller

A feature packed compact Advanced Lubrication Controller for small and medium lubrication systems

Key features:

- 3 Operating Modes: CYCLE, PULSE and FLOW

- Integrated LCD, all operating values set by simple menu parameters

- Multi-cycle capable

- NPN, PNP, Namur and simple switch inputs can be

- Min/Max Level Monitoring

- Prelube function

- Coded Remote Alarm System

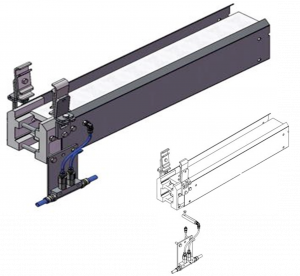

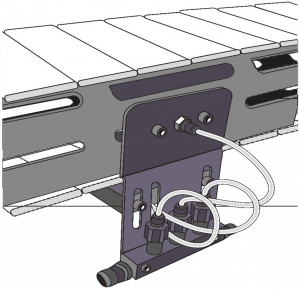

Chain and Accumulator Lubrication Kits

Designed to help customers cut water and electricity consumption, and reduce man-hours required for machine maintenance.

Traditional conveyor lubrication uses very high quantities of water mixed with oil, leaving both the equipment and factory floor very wet and slippery. With Specialist Lubricants Chain Lubrication Kit, the process is nearly completely dry.

There is no water involved, just tiny amounts of oil. 0.03 – 0.06CCs are directly injected in and on to the conveyor belt. This will reduce friction with the package and can double the life of the chain.

TPC21 Conveyor Kit

SL Part No. SL-PC21

Weight: 345g

Installation time: 10 mins

PC23 Conveyor Kit

SL Part No. SL-PC23

This kit can be installed while the chain is running, thereby ensuring minimal disruption to operations.

Weight: 866g

Installation time: 5 mins

UC24 Conveyor Kit

SL Part No. SL-UC24

Almost identical to the PC23 kit but having longer nylon and anodised plates. can also be installed while the chain is running.

Weight: 1092g

Installation time: 5 mins

HELIX Accumulator Kit

SL Part No. SL-HELIX

Weight: 366g

Installation time: 25 mins

Cardboard Packer Kit

SL Part No. SL-CBP

Weight: 319g

Installation time: 25 mins

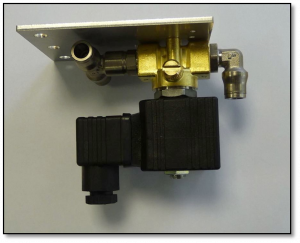

HYDRAULIC 2/2 VALVE 24 VDC ON MOUNTING PLATE

The Hydraulic 2/2 24 VDC Valve is used in Dry Lubrication systems to regulate the delivery of RM2000T to individual system points as required. The materials used have been selected for optimal performance and reliability.

Specialist Lubricants part no: SLVLV2

Composition:

- Brass Body

- Viton Seals

- Chromed Brass Tee Stud

- Chromed Brass Elbow Stud

- Stainless Steel Plate

- Plastic Casing

SL Start Up Kit

Designed for installations, this kit comes with tube cutters and a priming pump for priming the 4mm tube with lubricant to ensure even lubrication from the moment the system is turned on. It also has a useful selection of spare parts. Chromed brass fittings for 4mm and 8mm tube, and spare nylon and stainless steel blocks for kits.

Nylon tube

Available in 4mm and 8mm rolls, SL Nylon Tube is suitable for a vast range of applications.

Features & Benefits

- Lightweight and flexible

- Durable

- Heat and light stabilised materials

- Resistant to crushing, cracking abrasion and work hardening

- Good bend radii

- Suitable for push on and compression fittings

4mm White Nylon Tube is available in rolls of 30m. OD Tolerances: +0.02/-0.08mm

Burst Pressure: 1595 PSI/110 bar Bend Radius: 11mm

8mm Black Nylon Tube is available in rolls of 50m. OD Tolerances: +0.03/-0.10mm

Burst Pressure: PSI/ 122 bar Bend Radius: 32mm

8MM TUBE CONNECTORS AND STOPS

A selection of tubing connectors suitable for use in a diverse group of industries including food. Suitable for use with all fluids and gases including compressed air, grease, lubricants, water.

PUSH-IN

PUSH-IN

Composition: Nickel Plated Brass

Max Pressure: >60 Bar

Straight SL Part No. SL-FI-CN-S-P-8 Elbow SL Part No. SL-FI-CN-E-P-8 Tee SL Part No. SL-FI-CN-T-P-8

End Plug SL Part No. SL-FI-EN-P-8

COMPRESSION

COMPRESSION

Composition: Stainless Steel/Brass

Max Pressure: >80 Bar

Straight SL Part No. SL-FI-CN-S-C-8

Elbow SL Part No. SL-FI-CN-E-C-8

Tee SL Part No. SL-FI-CN-T-C-8

End Plug SL Part No. SL-FI-EN-C-8

STUDS COUPLINGS

A selection of Push-in tubing connectors suitable for use in a diverse group of industries including food. Suitable for use with all fluids and gases including compressed air, grease, lubricants, water. Solid construction and compact, external shapes easy to clean, components comply with FDA standard, and 1935/2004/EC regulation, excellent resistance to corrosion, individual unit quality control and dating in order to guarantee quality and traceability, RoHS.

Manufactured from FDA approved materials. Suitable for both polymer and metal (grooved) tubing. Abrasion and corrosion resistant. Compatible with a wide selection of chemicals. No tools required for connecting or disconnecting. Suitable for pressure and vacuum scenarios. FKM (FPM) Fluroelastomer Seals.

M6 Nylon Block with Inserts

M6 Nylon Block with Inserts

SL Part No. SL-LP-23

Weight: 197g

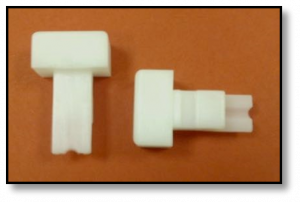

Nylon T-Piece

Nylon T-Piece

SL Part No. SL-TP-23

Weight: 5g

Nylon Brush

Nylon Brush

SL Part No. SL-BR

Weight: 6g

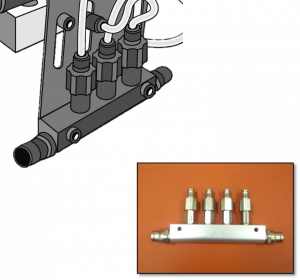

Dosing unit

Stainless steel fixed value metering valves ranging from 0.03, 0.06 and 0.1CC. Can be made to customer specifications from a single valve to eight. M4 mounting screws and nuts included.

All parts come with 5-year warranty on the condition that the operating instructions are followed and only RM2000T or RM2000MMF is used in the system.

DOWNLOAD 2021 BROCHURE HERE