Our PET system solutions offer you premium quality, minimum production costs and an optimal eco balance.

Using the PET-Line as a machine basis, you hold the key to the most highly productive preform systems. When designing a complete turnkey system, we collaborate on your behalf with leading industry and market partners.

Your benefits

The most advanced and highly productive system in the world

The system offers the broadest compatibility with existing side-entry molds and post-mold cooling stations. The system impresses with superlative output, exceptional energy efficiency, optimized processing of PET recyclates and an intuitive operating unit.

Highlights

- Clamping force sizes: 3000 kN, 4000 kN, 5000 kN

- Up to 144 cavities

- Electric clamping unit with 1.9 s lock-to-lock time

- Side removal unit with up to 4 post-mold cooling stations

- Energy efficient, two-stage injection unit

- New PETX screw for optimum processing of all PET types – with and without additives

- Latest generation Axos controller with innovative control concept

- Smart Operation for simpler, faster and safer start-up and production

- Lowest energy consumption on the market due to energy recuperation

- Comprehensive options package for custom enhancements

High-performance, high-precision and efficient

Productive, efficient & sustainable.

Reliably produce your preforms in excellent quality and with high availability, save energy costs and reduce your company's ecological footprint. While also benefiting from a large process window as well as low AA values and a low IV drop.

The most advanced and highly productive system in the world

The system offers the broadest compatibility with existing side-entry molds and post-mold cooling stations. The system impresses with superlative output, exceptional energy efficiency, optimized processing of PET recyclates and an intuitive operating unit.

Highlights

- Clamping force sizes: 3000 kN, 4000 kN, 5000 kN

- Up to 144 cavities

- Electric clamping unit with 1.9 s lock-to-lock time

- Side removal unit with up to 4 post-mold cooling stations

- Energy efficient, two-stage injection unit

- New PETX screw for optimum processing of all PET types – with and without additives

- Latest generation Axos controller with innovative control concept

- Smart Operation for simpler, faster and safer start-up and production

- Lowest energy consumption on the market due to energy recuperation

- Comprehensive options package for custom enhancements

High-performance, high-precision and efficient

Productive, efficient & sustainable.

Reliably produce your preforms in excellent quality and with high availability, save energy costs and reduce your company's ecological footprint. While also benefiting from a large process window as well as low AA values and a low IV drop.

The most advanced and highly productive system in the world

The system offers the broadest compatibility with existing side-entry molds and post-mold cooling stations. The system impresses with superlative output, exceptional energy efficiency, optimized processing of PET recyclates and an intuitive operating unit.

Highlights

- Clamping force sizes: 3000 kN, 4000 kN, 5000 kN

- Up to 144 cavities

- Electric clamping unit with 1.9 s lock-to-lock time

- Side removal unit with up to 4 post-mold cooling stations

- Energy efficient, two-stage injection unit

- New PETX screw for optimum processing of all PET types – with and without additives

- Latest generation Axos controller with innovative control concept

- Smart Operation for simpler, faster and safer start-up and production

- Lowest energy consumption on the market due to energy recuperation

- Comprehensive options package for custom enhancements

High-performance, high-precision and efficient

Productive, efficient & sustainable.

Reliably produce your preforms in excellent quality and with high availability, save energy costs and reduce your company's ecological footprint. While also benefiting from a large process window as well as low AA values and a low IV drop.

The most advanced and highly productive system in the world

The system offers the broadest compatibility with existing side-entry molds and post-mold cooling stations. The system impresses with superlative output, exceptional energy efficiency, optimized processing of PET recyclates and an intuitive operating unit.

Highlights

- Clamping force sizes: 3000 kN, 4000 kN, 5000 kN

- Up to 144 cavities

- Electric clamping unit with 1.9 s lock-to-lock time

- Side removal unit with up to 4 post-mold cooling stations

- Energy efficient, two-stage injection unit

- New PETX screw for optimum processing of all PET types – with and without additives

- Latest generation Axos controller with innovative control concept

- Smart Operation for simpler, faster and safer start-up and production

- Lowest energy consumption on the market due to energy recuperation

- Comprehensive options package for custom enhancements

High-performance, high-precision and efficient

Productive, efficient & sustainable.

Reliably produce your preforms in excellent quality and with high availability, save energy costs and reduce your company's ecological footprint. While also benefiting from a large process window as well as low AA values and a low IV drop.

The most advanced and highly productive system in the world

The system offers the broadest compatibility with existing side-entry molds and post-mold cooling stations. The system impresses with superlative output, exceptional energy efficiency, optimized processing of PET recyclates and an intuitive operating unit.

Highlights

- Clamping force sizes: 3000 kN, 4000 kN, 5000 kN

- Up to 144 cavities

- Electric clamping unit with 1.9 s lock-to-lock time

- Side removal unit with up to 4 post-mold cooling stations

- Energy efficient, two-stage injection unit

- New PETX screw for optimum processing of all PET types – with and without additives

- Latest generation Axos controller with innovative control concept

- Smart Operation for simpler, faster and safer start-up and production

- Lowest energy consumption on the market due to energy recuperation

- Comprehensive options package for custom enhancements

High-performance, high-precision and efficient

Productive, efficient & sustainable.

Reliably produce your preforms in excellent quality and with high availability, save energy costs and reduce your company's ecological footprint. While also benefiting from a large process window as well as low AA values and a low IV drop.

The most advanced and highly productive system in the world

The system offers the broadest compatibility with existing side-entry molds and post-mold cooling stations. The system impresses with superlative output, exceptional energy efficiency, optimized processing of PET recyclates and an intuitive operating unit.

Highlights

- Clamping force sizes: 3000 kN, 4000 kN, 5000 kN

- Up to 144 cavities

- Electric clamping unit with 1.9 s lock-to-lock time

- Side removal unit with up to 4 post-mold cooling stations

- Energy efficient, two-stage injection unit

- New PETX screw for optimum processing of all PET types – with and without additives

- Latest generation Axos controller with innovative control concept

- Smart Operation for simpler, faster and safer start-up and production

- Lowest energy consumption on the market due to energy recuperation

- Comprehensive options package for custom enhancements

High-performance, high-precision and efficient

Productive, efficient & sustainable.

Reliably produce your preforms in excellent quality and with high availability, save energy costs and reduce your company's ecological footprint. While also benefiting from a large process window as well as low AA values and a low IV drop.

The most advanced and highly productive system in the world

The system offers the broadest compatibility with existing side-entry molds and post-mold cooling stations. The system impresses with superlative output, exceptional energy efficiency, optimized processing of PET recyclates and an intuitive operating unit.

Highlights

- Clamping force sizes: 3000 kN, 4000 kN, 5000 kN

- Up to 144 cavities

- Electric clamping unit with 1.9 s lock-to-lock time

- Side removal unit with up to 4 post-mold cooling stations

- Energy efficient, two-stage injection unit

- New PETX screw for optimum processing of all PET types – with and without additives

- Latest generation Axos controller with innovative control concept

- Smart Operation for simpler, faster and safer start-up and production

- Lowest energy consumption on the market due to energy recuperation

- Comprehensive options package for custom enhancements

High-performance, high-precision and efficient

Productive, efficient & sustainable.

Reliably produce your preforms in excellent quality and with high availability, save energy costs and reduce your company's ecological footprint. While also benefiting from a large process window as well as low AA values and a low IV drop.

Applications

2K Applications

For barrier technologies, Two components in one manifold

Special molds

Article development, Mold design, Hotrunner design, Nozzles and Micro-injection

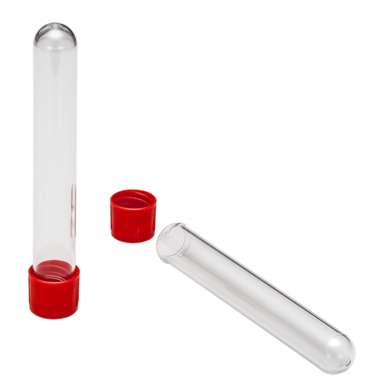

Vacuum blood tubes

Special PET types/additives, Thickness < 1mm, Ratio up to 120, Quality, Requirements for medical applications

Different types of resin

Preforms made of PP, PE, PLA, barrier technology , Pharma applications, Toner cartridges and more